Pearson PTE Test vs IELTS & TOEFL and their difrences

There are three major English proficiency tests, IELTS, TOEFL, and PTE. Here we are comparing the most popular English language tests.

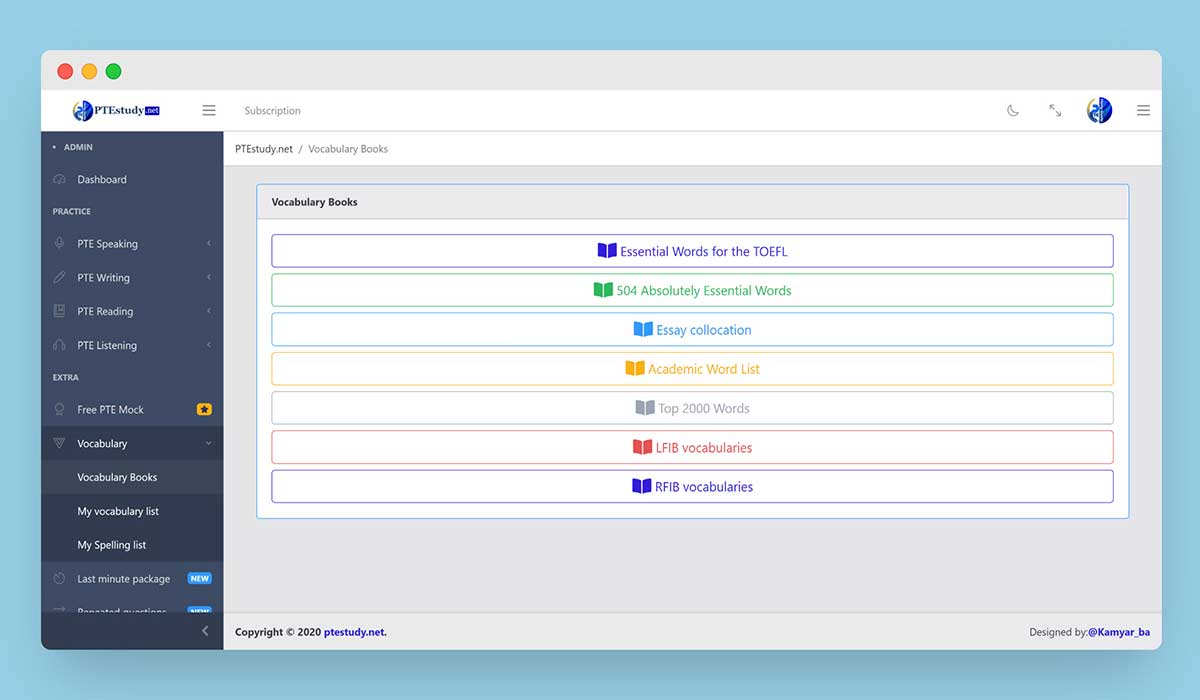

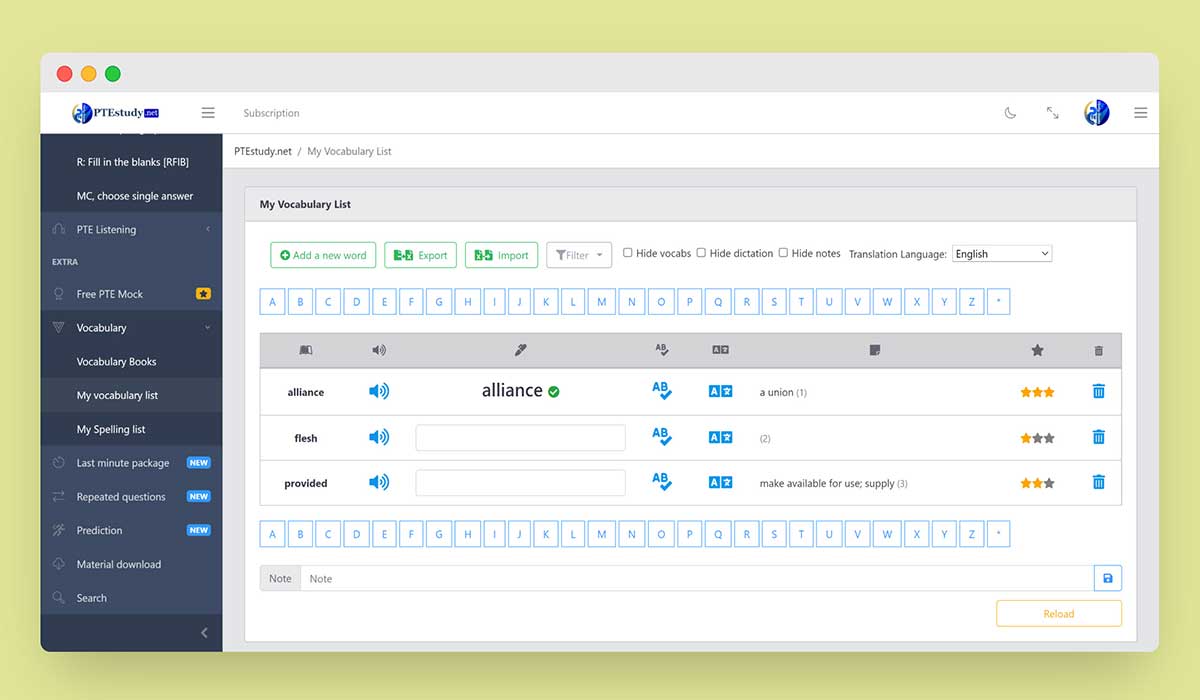

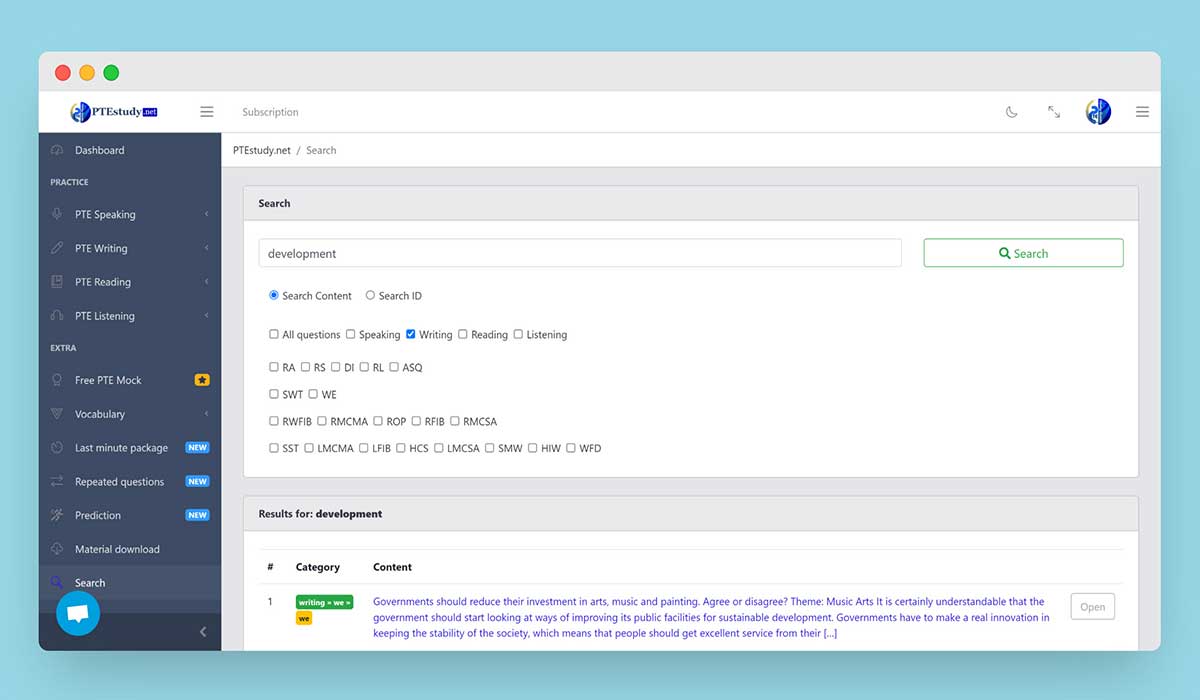

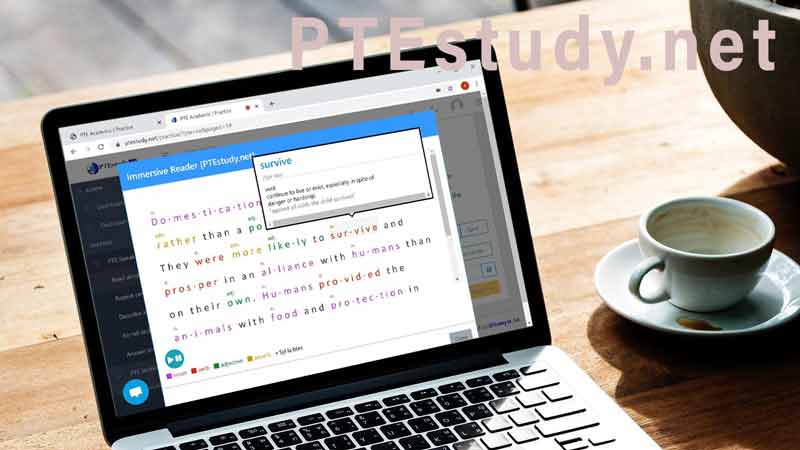

Read moreImprove your communicative and time management skills in PTE exam with more than 10000 recent and repeated questions in a simulated format of the exam

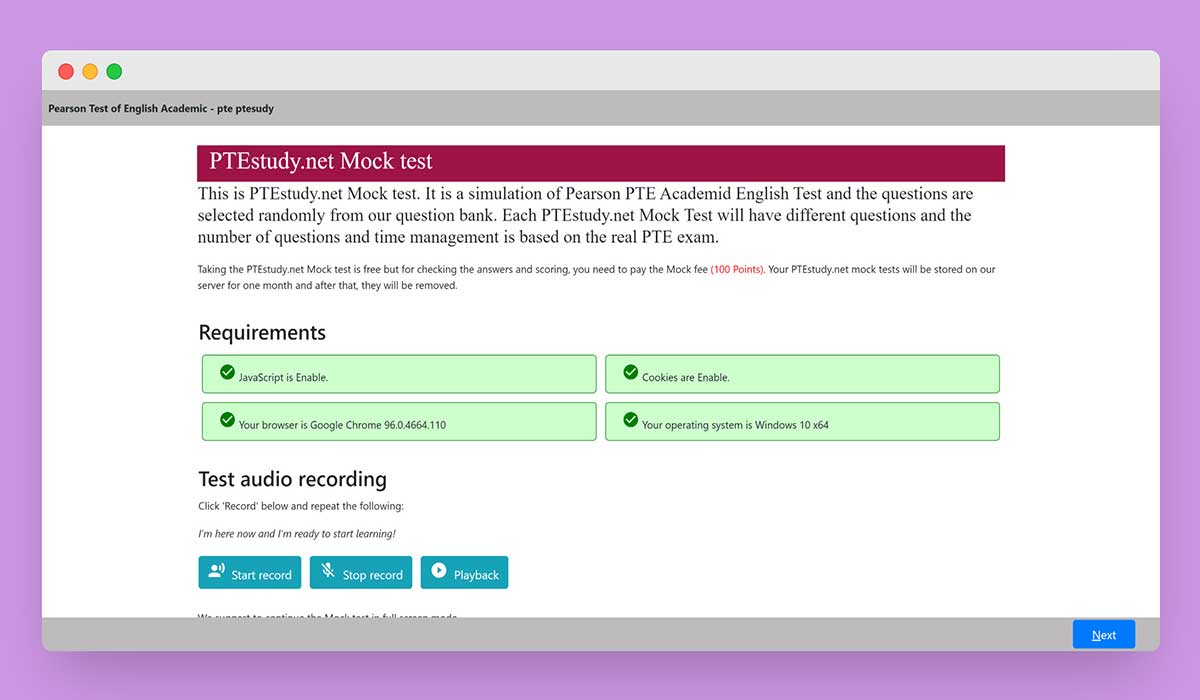

Free PracticeAchieve your desired score for your upcoming PTE Exam!! Scored Pte Mock Test will help you check your current PTE score level and identify your weaknesses.

Take PTE Mock testConsult with our PTE experts to identify your weaknesses, analyze your score and make a precise plan to start your journey to success

Read moreFollow These Tips to Improve Your PTE-A Speaking Score

Last month PTE real questions collected by test takers all around the world.

New versions of materials in all skills released continuously- available all materials for free.

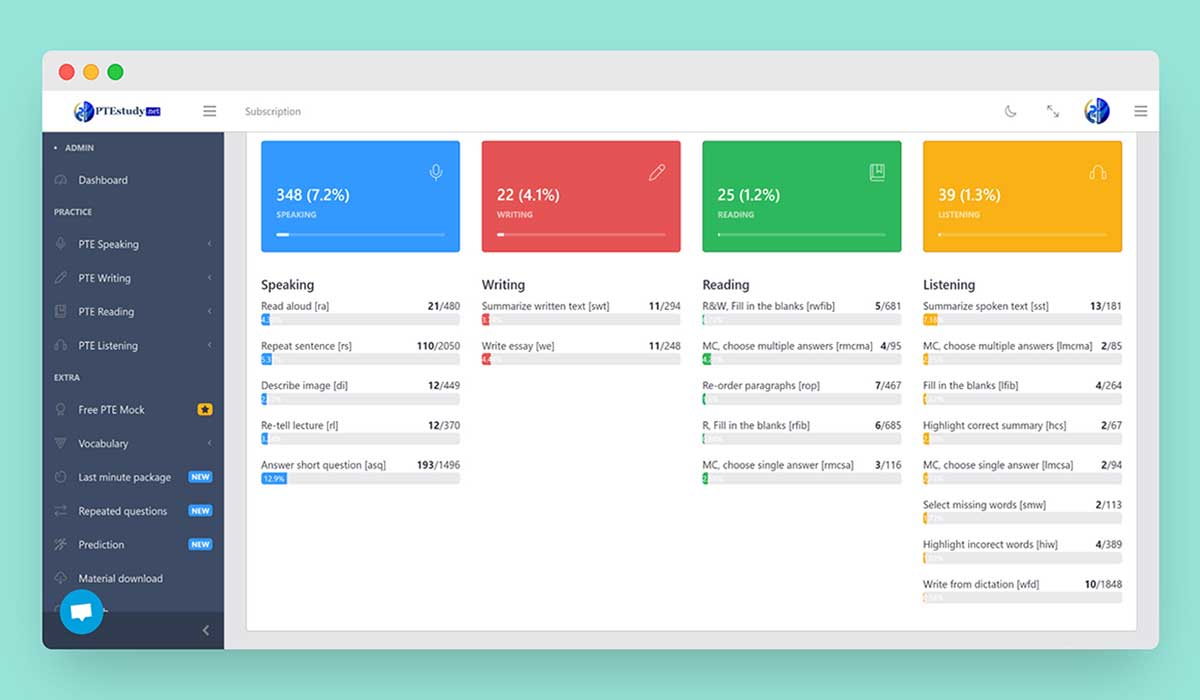

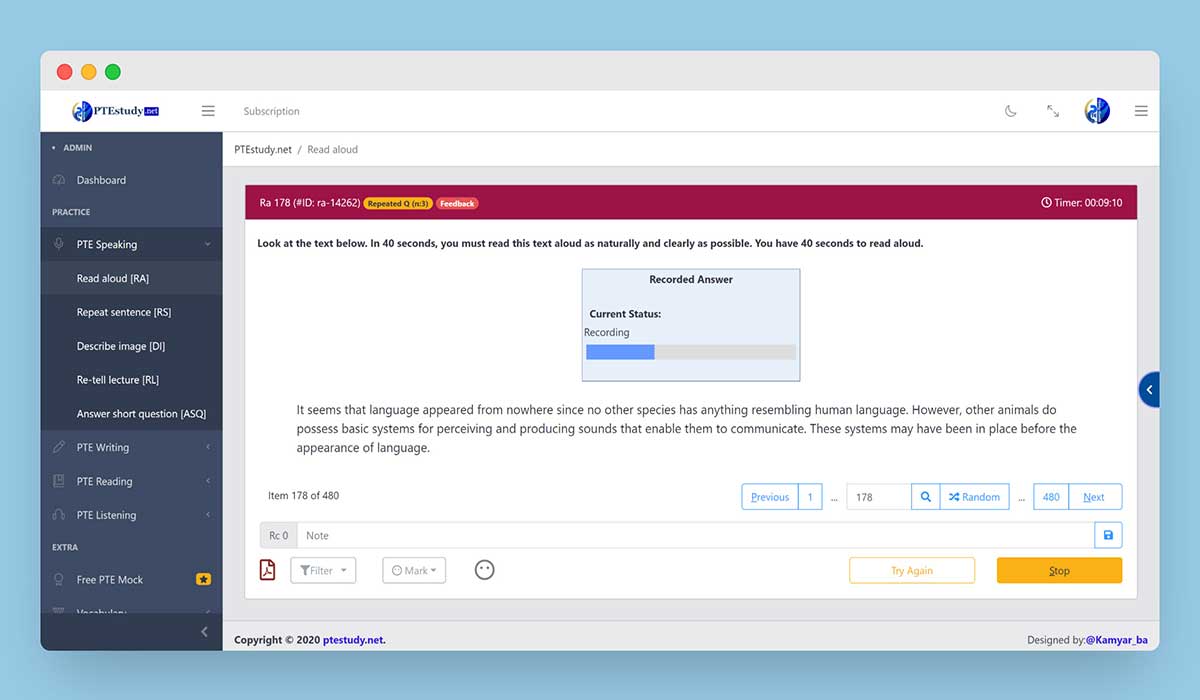

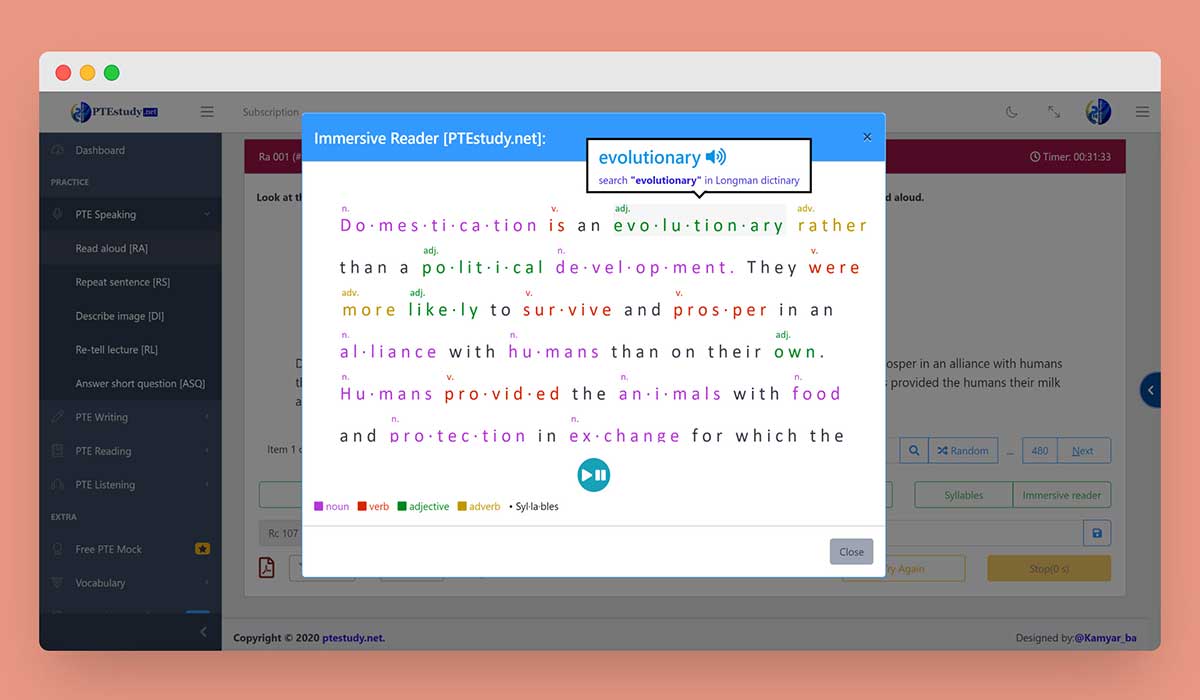

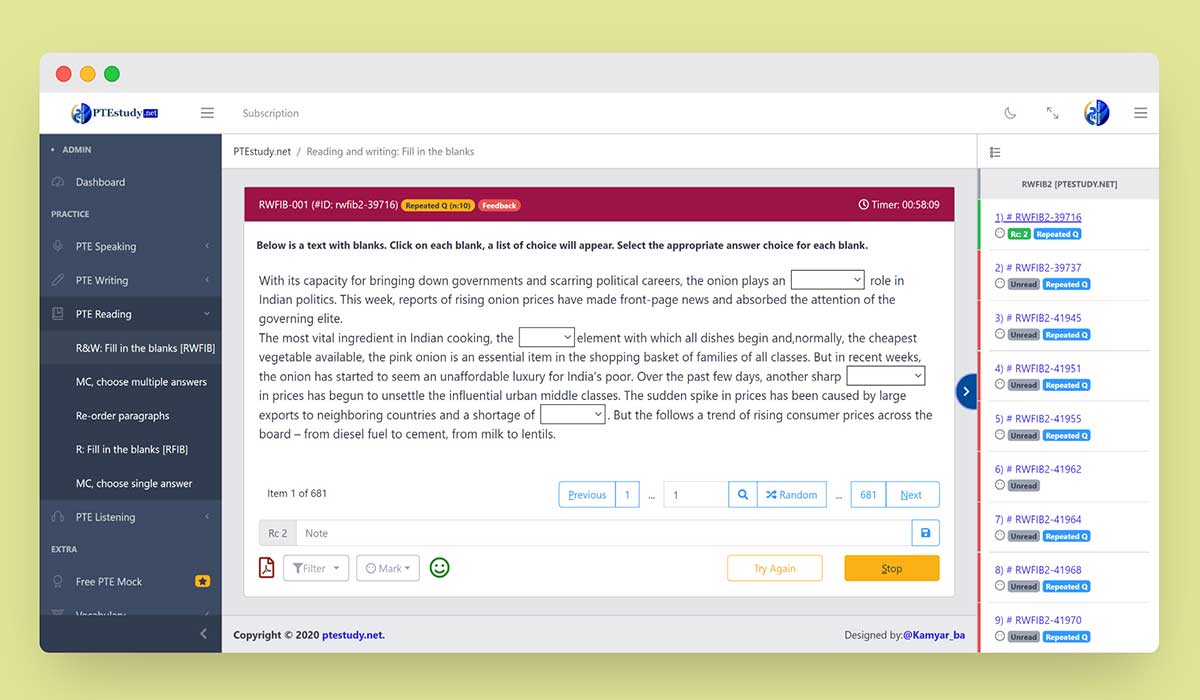

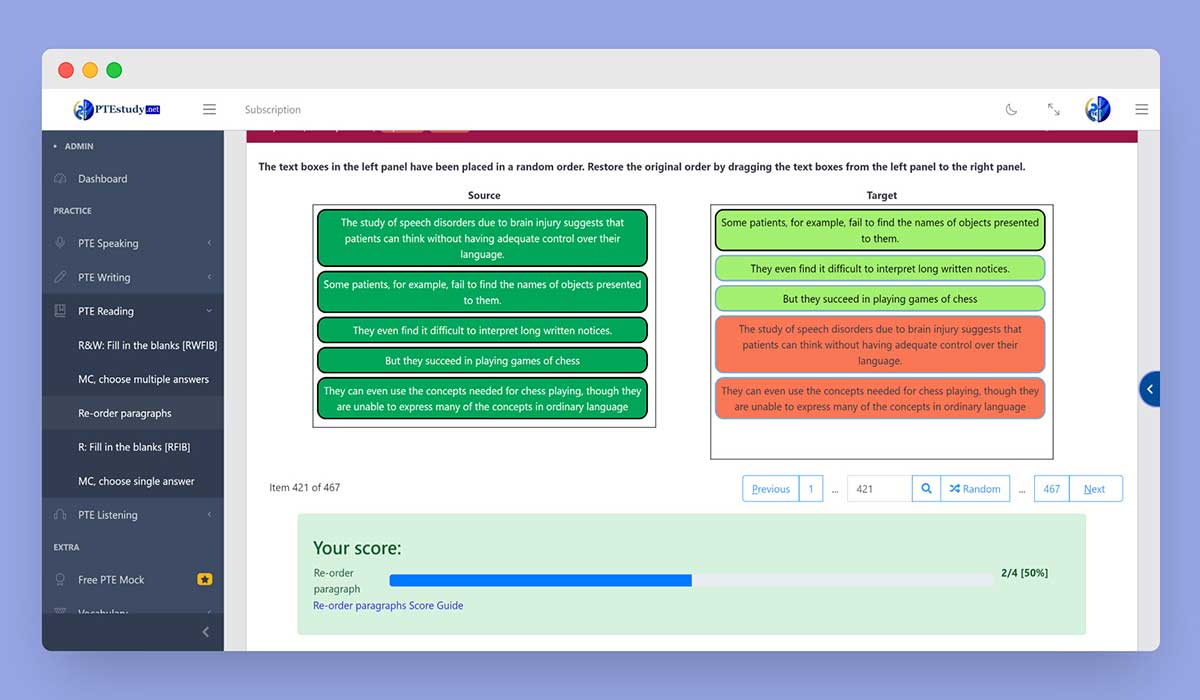

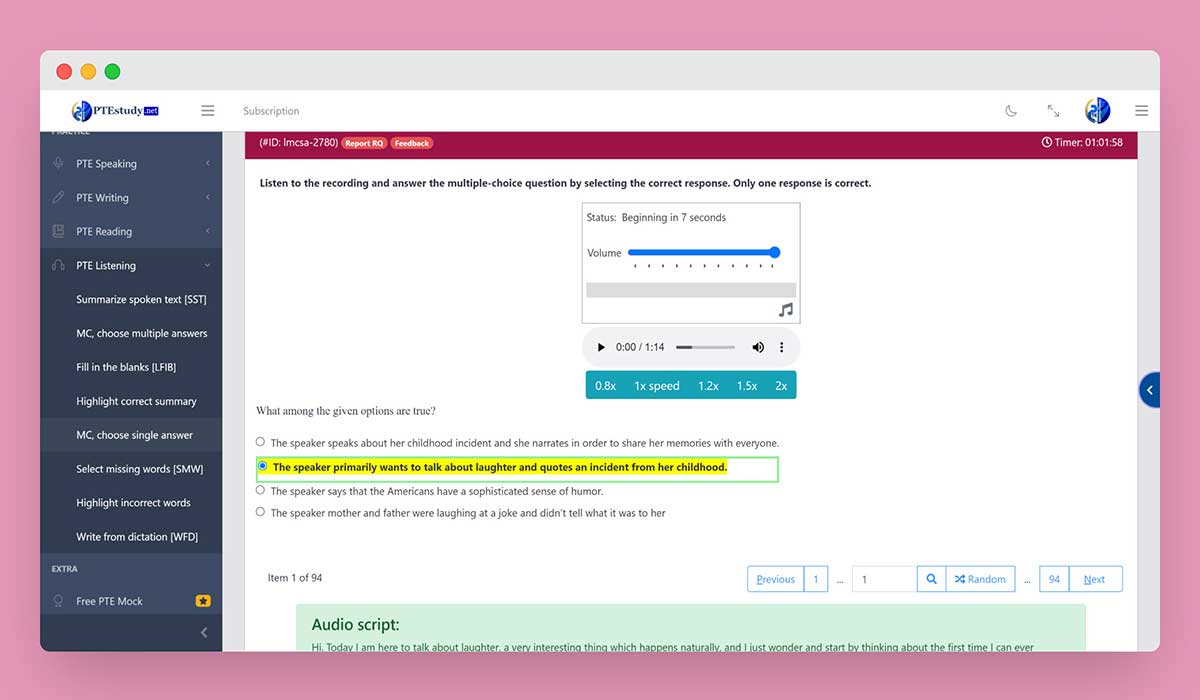

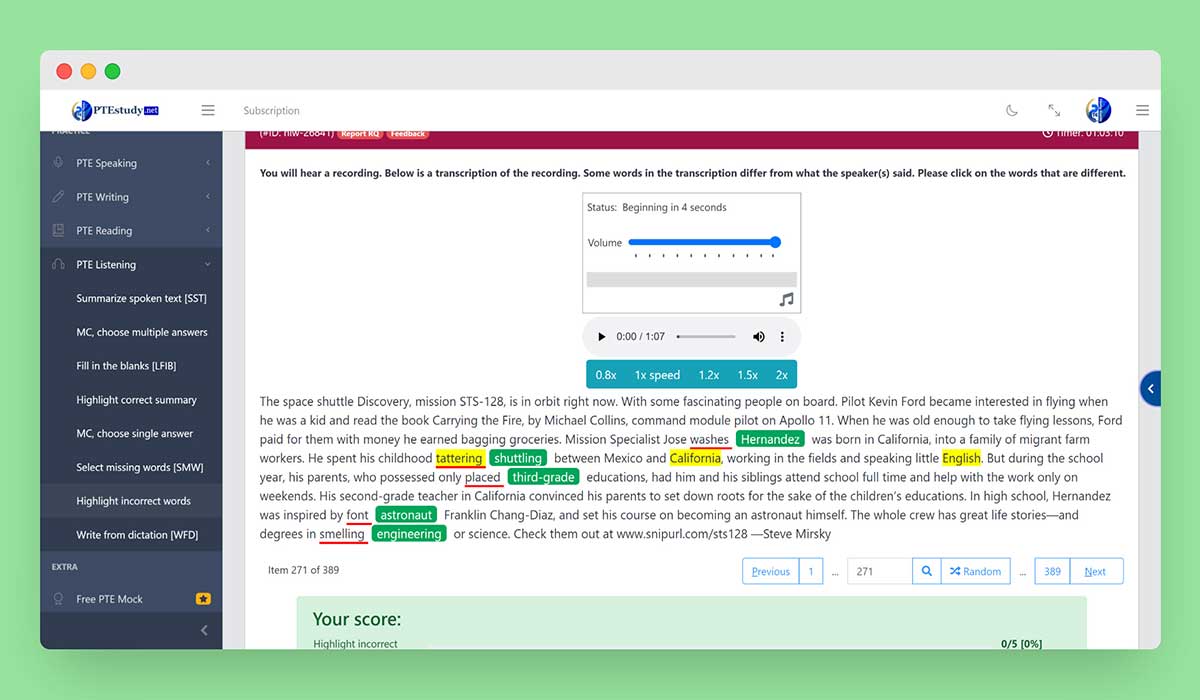

Practice like in the original test format and improve your score to get +65, +79, or perfect 90.

✔ FREE Standard Mock Test

✔ FREE Optional Mock Test

✔ Simulate Pearson scoring engines

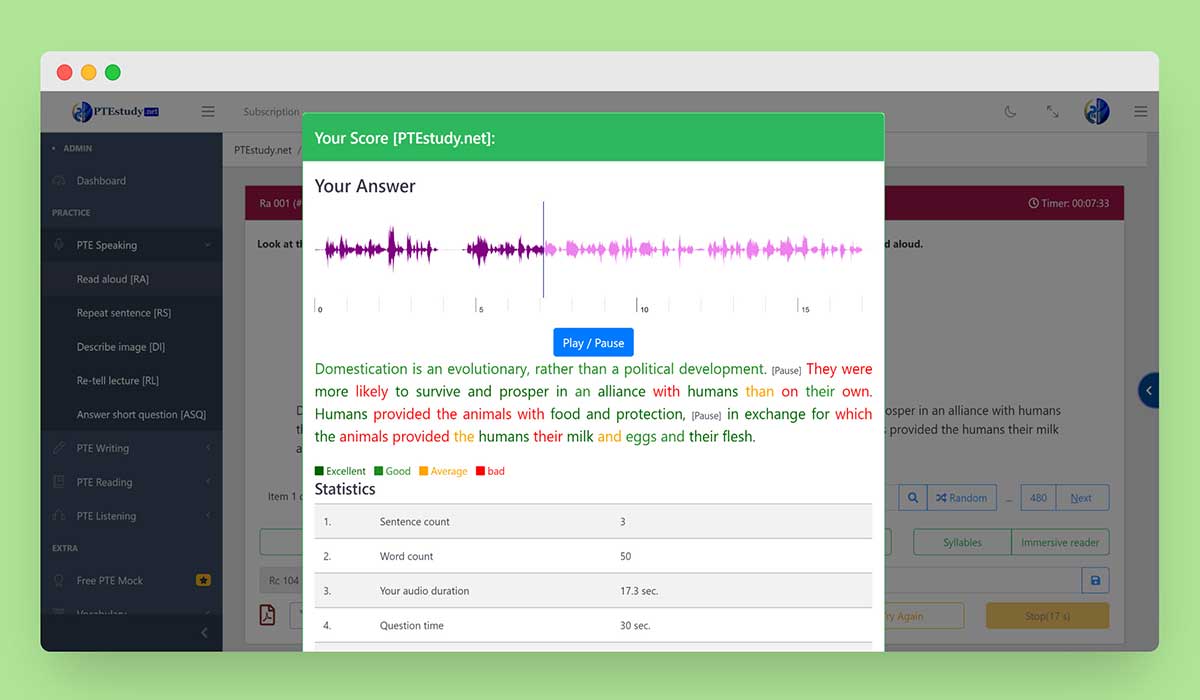

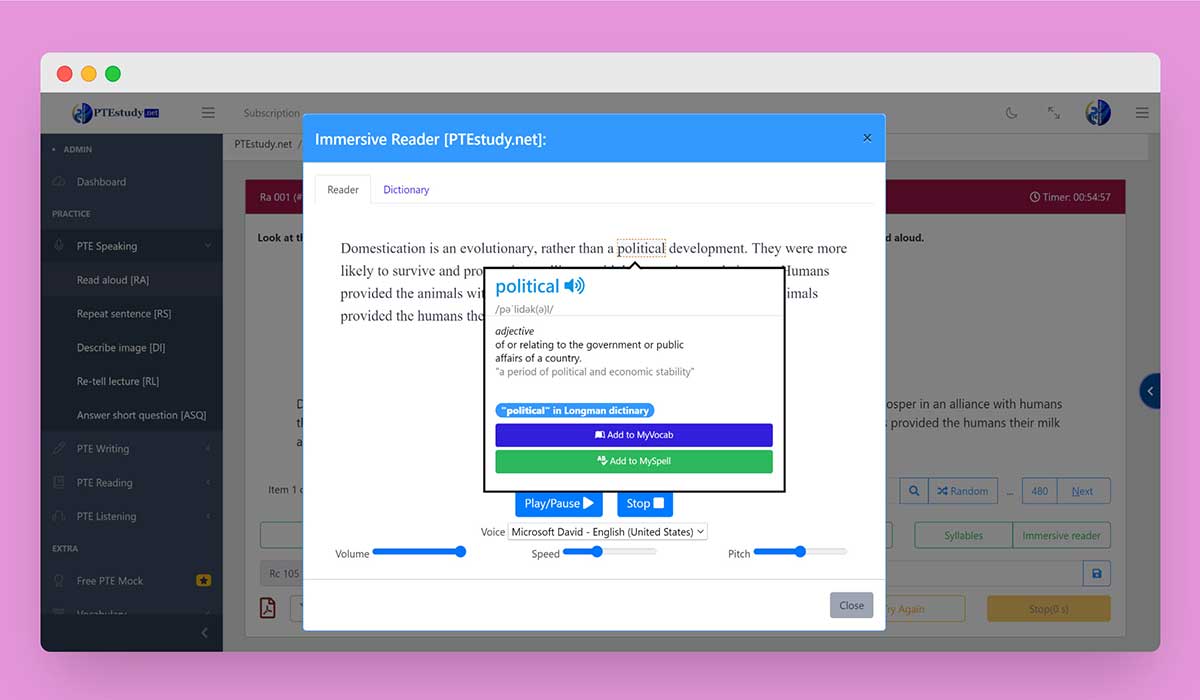

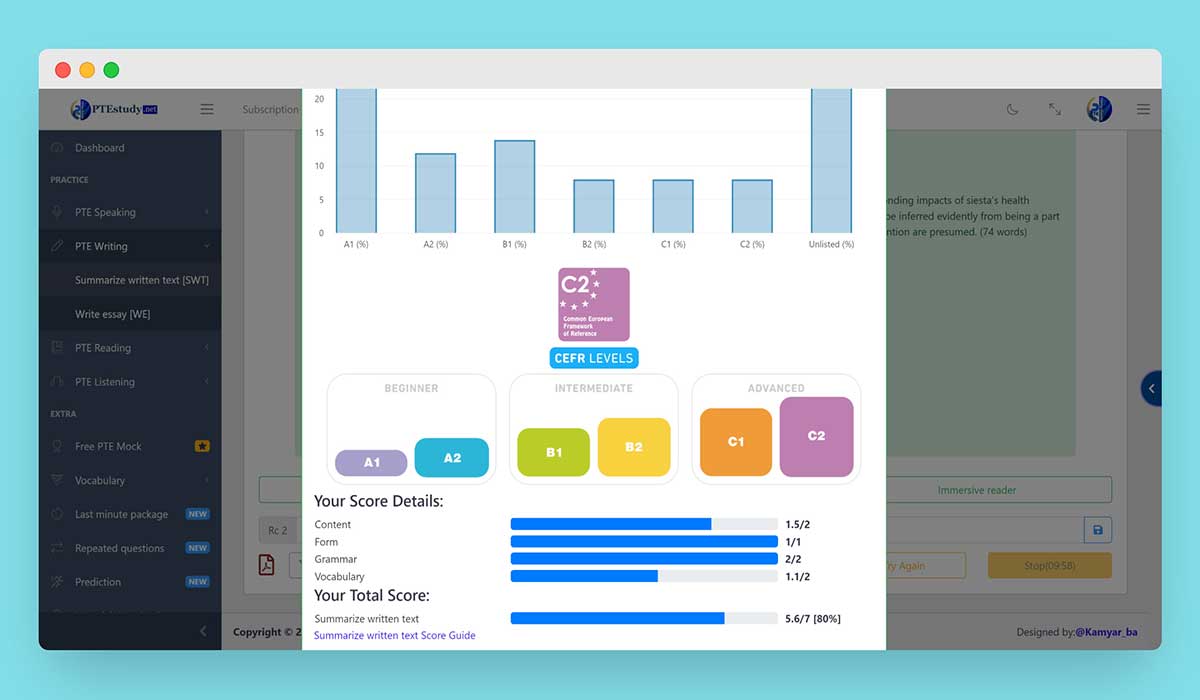

AI scoring engine gives Results according to audio responses in terms of content, pronunciation, and fluency.

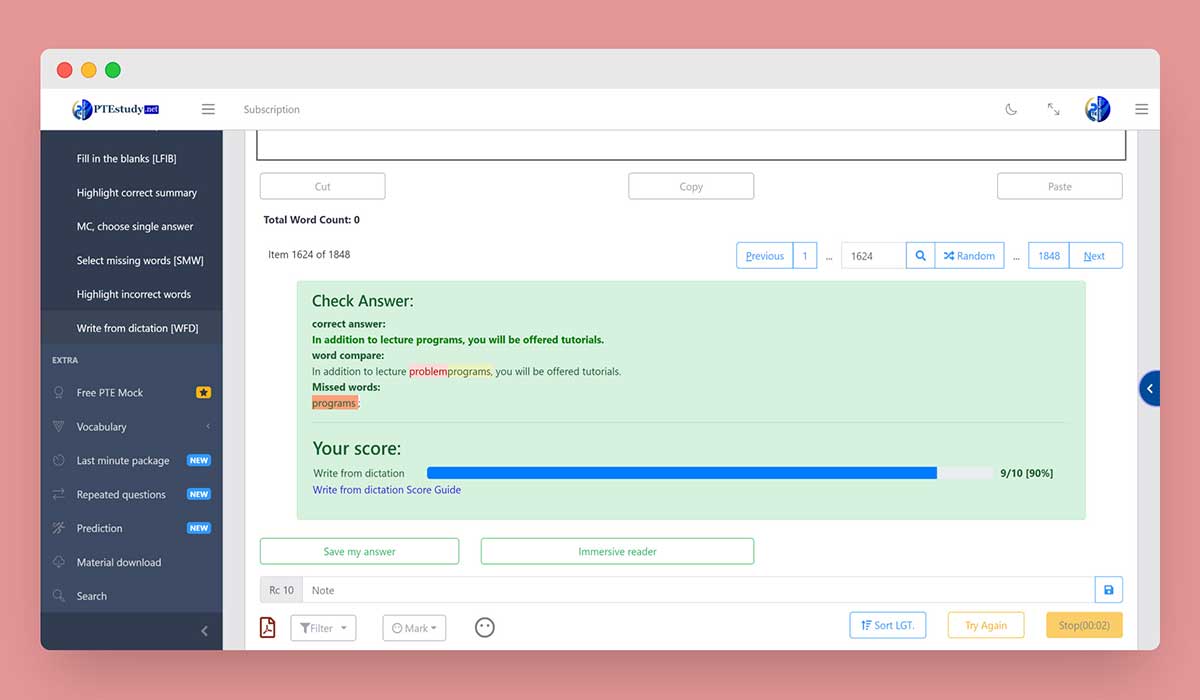

AI scoring engine gives results such as content, form, grammar, spelling, vocabulary range, general linguistic range, and development structure and coherence

We help candidates just like you to feel confident in PTE language exam, even if they’ve only just started learning. We have provided a platform for online practice and gathered real and repeated questions.

Simulate Pearson scoring engines

View Practice Score and Answer Explanations

Evaluate speaking pronunciation and fluency

Check writing grammar and spelling

Weekly Performance evaluation

There are three major English proficiency tests, IELTS, TOEFL, and PTE. Here we are comparing the most popular English language tests.

Read more

Best Tips to help you score 79+ in all sections of PTE! All you need is to keep on practicing for the sections in which you are weak.

Read more

PTE Exam format will divide the test into three parts which are listening, reading, and writing & speaking.

Read moreHello, I have got my desired score, thank you for the wonderful website especially Lmp, I have got many questions from this website, thank you once again.

Ptestudy is a amazing group which help students who require help in this filed, these angels make an indescribable sense without no expectation….. I hope i can do the best in the exam…

In three months, I got my desired score! Many thanks to all the PTE study team (website, didactic, and private classes) Make sure you are a specially distinguished team! All the best to you!

I studied from ptestudy.net and I passed the exam. It helped so much. Thank you very much again. I appreciate it. Have a nice day.

this article is perfect for gaining some knowledge about PTE

On behalf of many other English learners, as well as PTE-Academic test takers, I really appreciate your endeavor for designing such a helpful website.

Hello… The support is really approachable and friendly. You have your questions answered in less than a couple of minutes. I really appreciate that…